February 2023 Visit on Friday, February 10, 2023

Experiment Leads: Daniel Krajovic and Joanna White

Our February 2023 visit focused on polymer science, especially pertinent to the class’s theme of environmental science given the plastic pollution problem. Joanna and Daniel, both involved in polymer research, led the lesson and began by overviewing their work to the students. Joanna then went into some nitty-gritty details on polymers, explaining the concept of monomer repeat units making up a macromolecule. She also told the students about the A-B-A-B-... connections of monomers in step-growth polymerization, which was nicely exemplified by Nylon-6,6 and polyurethane, and she gave some examples of plastics that show up in everyday life that the students might not have realized. Then, Daniel talked about plastic pollution and the importance of sustainability in polymer design, outlining strategies for combating the existing issues, including his lab work at UMN targeting novel or improved properties of nontraditional, more sustainable polymers. He also explained how scientists take cues from degradable polymers in nature, such as cellulose, silk, and starch, to make synthetic polymers degradable in an effort to keep them out of landfills. Finally, Daniel previewed the exciting demo activities that the students conducted with the help of SFA volunteers- syntheses of Nylon-6,6 and polyurethane, the very same model polymers that Joanna had detailed!

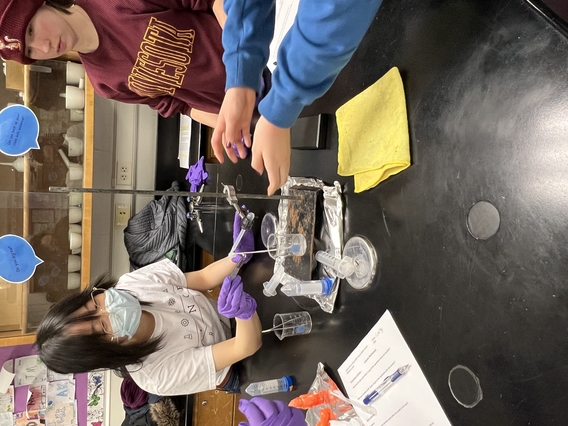

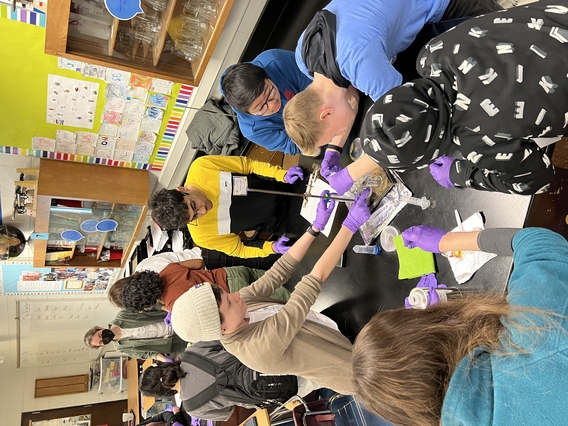

For the Nylon-6,6 synthesis, the students began by pouring an aqueous solution of hexamethylene diamine (HDA) into a beaker. Then, they carefully poured in a solution of adipoyl chloride (AC) in cyclohexane, which was less dense than the aqueous layer, so that it sat on top, forming a meniscus. The students then poked tweezers into the meniscus and pulled out a solid: the Nylon-6,6! At the liquid interface, the HDA and AC molecules react to form the polymer, and then when it’s pulled out, the liquids have room to contact each other again, which continuously creates polymer and allows a solid rope to be pulled out from the liquids.

One student reflected, “This is the coolest science I’ve ever seen!” The students investigated how the spooling speed affected the quality of the rope. In addition, they were tasked with figuring out which side of the room had more AC in its solutions. The two sides had different AC solutions, marked either with orange or green tape, with different AC concentrations. After using small balances to weigh the Nylon-6,6 that they had produced, the students with green-capped AC vials reported an average of ~4 grams, while the students with orange-capped AC vials reported an average close to 10 grams. With this result, the class correctly concluded that the orange-capped solutions contained more AC, as the reaction requires 1:1 HDA:AC, and the AC was scarcer in the green-capped solutions.

One student reflected, “This is the coolest science I’ve ever seen!”

Meanwhile, Clare had prepared mixtures of a polyurethane precursor and food coloring in several scintillation vials before the lesson. As the students worked on their Nylon-6,6 synthesis, she went around to the tables and stirred in the second reactant to initiate a similar step-growth polymerization. Over the course of the demo, the reaction proceeded, forming polyurethane and generating CO2, which caused foaming. The mixtures safely overflowed onto the lab benches and finally solidified, forming brightly colored polyurethane foam!