03.26.19

Experiment leaders: Bernie & Neil

In this visit to Venture Academy, SFA introduced students to mechanics, the study of how objects move and change shape in response to forces. Bernie introduced the class to the concept of deformation (i.e., shape change) of materials and how engineers often use a tensile test to quantify a material’s stiffness, or how much the material deforms in response to an applied force.

Students were then given Twizzlers and gummy worms to perform tensile tests of their own. Before beginning the experiment, students were asked to feel the differences between the two candies and hypothesize which they thought was a stiffer material. In many cases, students argued that Twizzlers were the stiffer material because they were harder to stretch, and anecdotally, were much more difficult to tear into pieces when taking a bite.

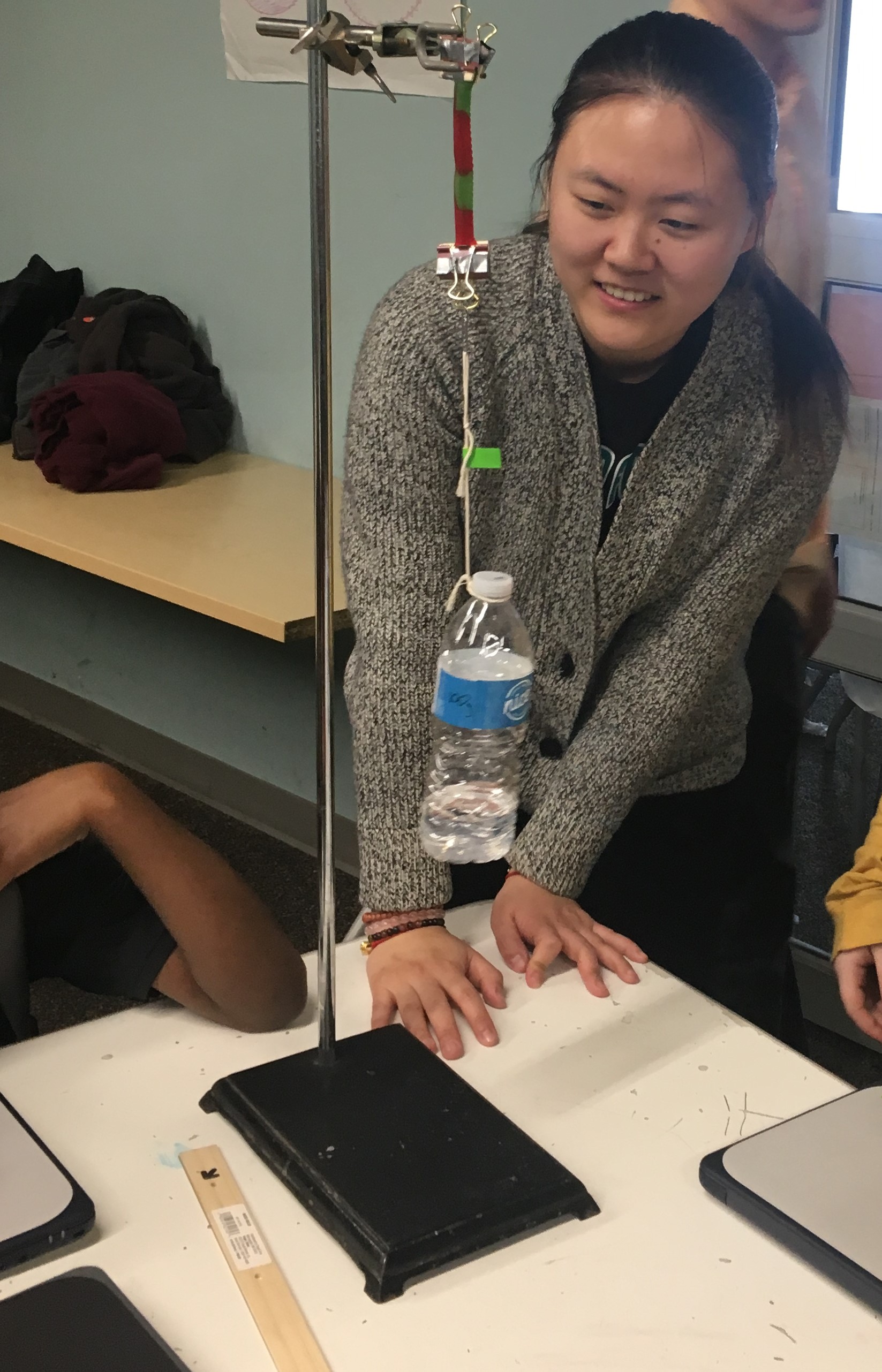

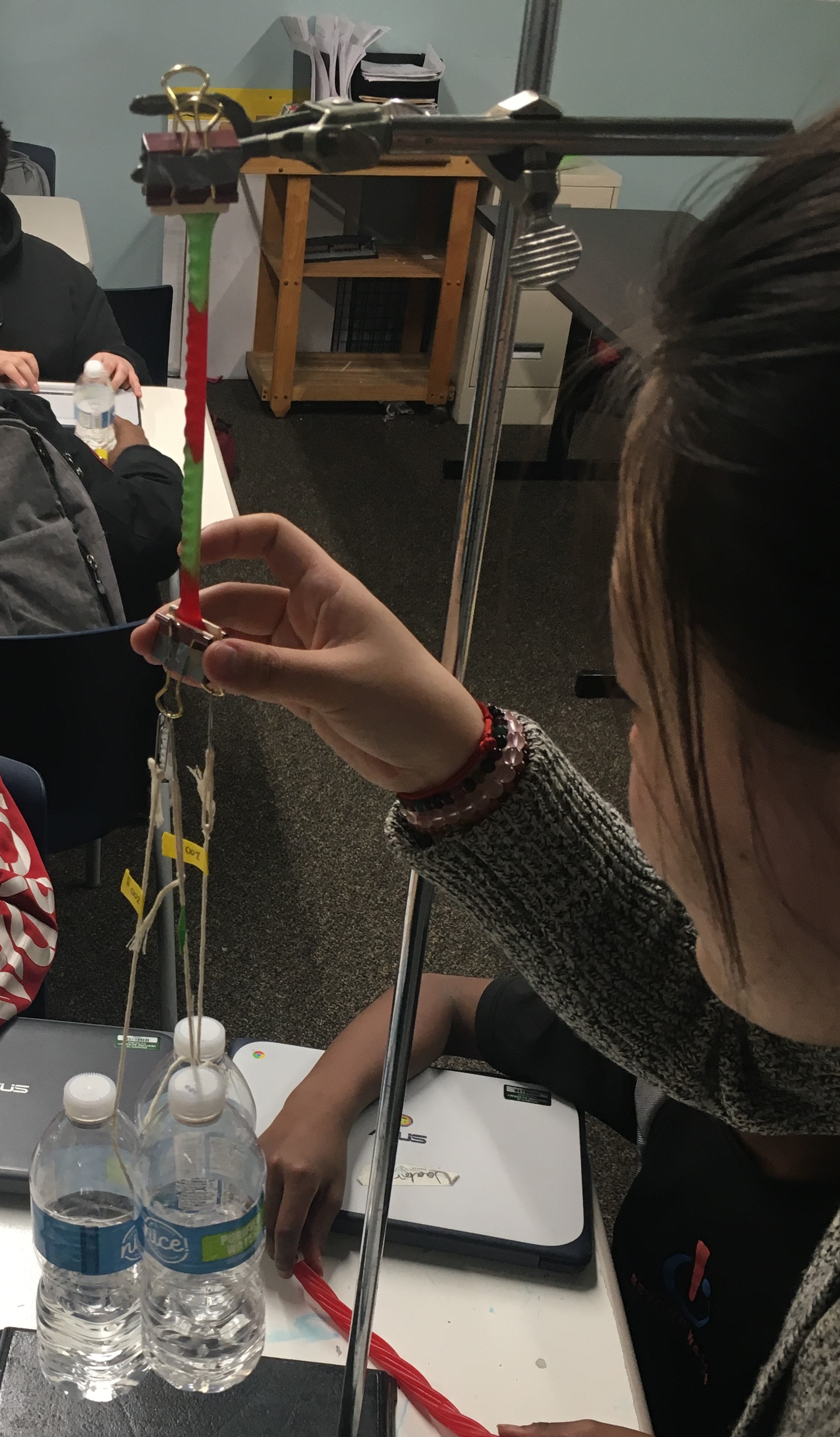

To test their hypotheses, students attached their candies to the tensile testing apparatus, recorded the initial length of the candy, and sequentially added weight (water bottles filled w/increasing volume of water) to the bottom of candy. With each weight added, students measured the new length of the candy and calculated how much the candy elongated in response to the added weight. Using the collected data, students graphed force vs. displacement for each candy and determined the stiffnesses of each candy as the slope of the respective force-displacement curve. With their tests, students found that their data supported their hypotheses – sweet, right?

Along the way, various other topics were introduced. During tensile tests, some candies broke, at which point SFA volunteers discussed the concept of “failure,” or the point at which a material can no longer handle an applied force causing it to break. Moreover, students were given peel-apart Twizzlers and were asked to perform tensile tests 1) on the entire piece of candy, and 2) on the candy after portions of it had been peeled away. Notably, students pointed out that the same type of material was apparently displaying different stiffness behaviors – here, SFA introduced the concept of “stress” and “strain” as ways to account for the cross-sectional area and length of a material to ensure that one type of material can be described by a stiffness measure regardless of its size.

Neil wrapped up the experiment by asking the class which materials they initially thought were going to be stiffer, why they thought that, and whether their tests supported these hypotheses. Moreover, he asked about why the peel-apart Twizzlers often seemed to fail at lower applied weights in comparison to their smaller Twizzler and gummy bear counterparts – one student proposed that it could be due to the multi-stranded construction of the candy, positing that failure of one strand could lead to failure of the entire material (a concept students often won’t learn until college). Evidently, students walked away with an understanding of deformation & how engineers might quantify it, a higher-level understanding of what structural properties might lead to failure, and with some extra sweets.

Experimenting with candy was an exciting way to stretch students’ knowledge without too much added stress – looking forward to our last visit of the school year in April!